Who We Are

Amian, a brand of ACI Agrolink Limited is a name of trust to its customers around the globe. The shrimp processing factory is at the heart of the shrimp farming hub allowing shrimp to be processed immediately after shrimp receive; ensuring the premium quality shrimp to the world. With professional industry expertise, international quality control facilities and best hands on shrimp processing, Amian brand shrimp is setting a benchmark in terms of quality and food safety.

ACI Agrolink Limited, a subsidiary of ACI Limited is a unique name in Bangladesh for its quality products, innovation, skilled professional management, work culture, business ethics and environmental consciousness. The state-of-the-art factory is designed to deliver the highest level of quality standard and meet the specific needs of the customers.

The factory is a 53,878 sq. ft building with the production capacity of 30 ton per day.

ACI Limited is one of the leading conglomerates with a multinational heritage and has always been driven by its mission, vision and values. ACI’s international recognition also enables Amian Shrimp to ensure all global compliances and certifications, creating a hub of satisfied customers worldwide. The company owns multidimensional facilities to create and deliver the best range of products for its global partners through ensuring premium quality, unwavering commitment and continuous innovation.

Our suppliers are chosen from those who comply with the laws of employment and protection of environment. We encourage and assist our suppliers in becoming more efficient. We ensure that our suppliers provide us materials which conform to the highest standards.

We take care of environmental compliance. There are policies for quality, safety, Health and Environment which are followed meticulously.

ACI Agrolink Limited, a subsidiary of ACI Limited is a unique name in Bangladesh for its quality products, innovation, skilled professional management, work culture, business ethics and environmental consciousness. The state-of-the-art factory is designed to deliver the highest level of quality standard and meet the specific needs of the customers.

The factory is a 53,878 sq. ft building with the production capacity of 30 ton per day.

ACI Limited is one of the leading conglomerates with a multinational heritage and has always been driven by its mission, vision and values. ACI’s international recognition also enables Amian Shrimp to ensure all global compliances and certifications, creating a hub of satisfied customers worldwide. The company owns multidimensional facilities to create and deliver the best range of products for its global partners through ensuring premium quality, unwavering commitment and continuous innovation.

Our suppliers are chosen from those who comply with the laws of employment and protection of environment. We encourage and assist our suppliers in becoming more efficient. We ensure that our suppliers provide us materials which conform to the highest standards.

We take care of our environment. All our factories and compliant of the environmental laws. There are policies for quality, safety, Health and Environment which are followed meticulously.

The shrimp processing plant is established with 53,878 sq ft building of which 35,621 sq ft is UCRETE lapping production floor able to produce 30 MT per day. The UCRETE floor, built upon German technology, ensconces no food contamination, impervious, non-absorbent, anti-microbial production area.

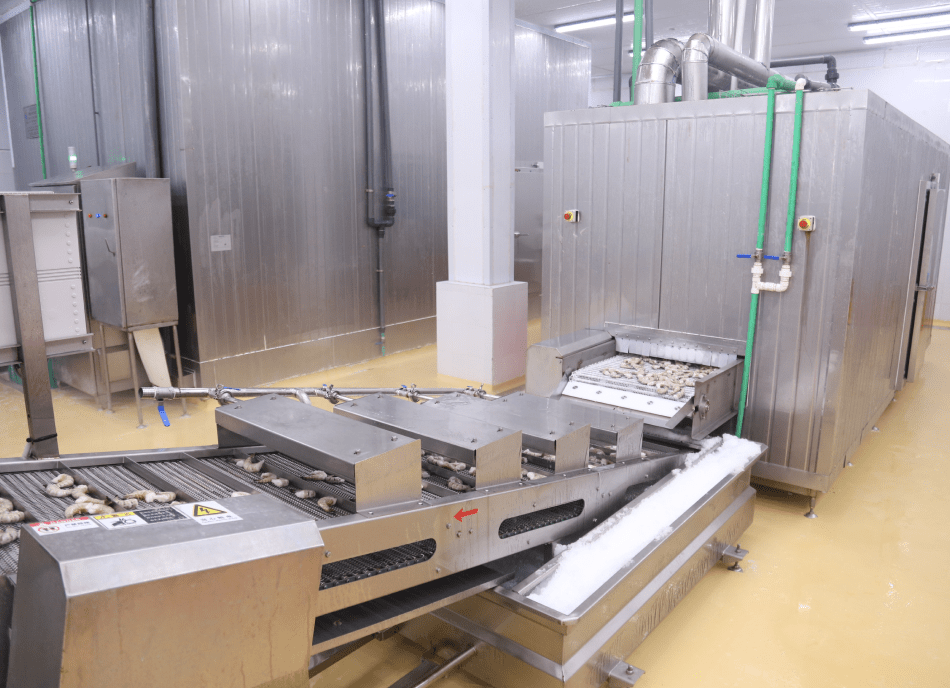

The plant is equipped with two best classes Plate Freezers from Mycom, Japan and World base, China each of which has the capacity to freeze 500 kg per load in 1.5-2 hours and blast freezer from UK with the ability to freeze 4 MT per load in 3-3.5 hours. This facility is also equipped IQF Freezer from NTSQUARE, China having 500 kg/hr freezing capacity with two glazing & hardening chamber and one steam cooking line, 300kg/hr. The product core temperature is maintained -18oC in every freezing process line to extend the product shelf life and its quality.

Amian shrimp is furnished with two cold storages, each of which has the capacity to hold 250 MT where temperature maintain between -18 to -22o C. Combined total 12 units compressors concocted refrigeration system, 10 units from SABROE, Denmark and 2 units from KILOSKAR, India, ensures European standard cooling system. It has two chill storages of 450 sq ft each for raw materials along with a dry storage of 1000 sq ft for packaging and additives.

The in-house water treatment plant (WTP), RO and UV system is used for the water treatment system which supplies safe water to every phase of the production process ensuring the best quality salubrious product.

Two flake ice plants with 40 MT capacity per day with ice formed with in-house WTP treated water, indemnify the ice production for the entire production process to ensure the best quality product.

The factory is equipped with in-house sub-station, facilitate with 630 KVA transformer, for electricity supply. Two stands by generator from YORPOWER, UK with 550 KVA and FMW, China with 60 KVA and also solar power secure uninterrupted 24-hour power back up.

It has also Effluent Treatment Plant (ETP) to purify waste water and release safe water to environment to protect the nature.

The shrimp processing plant is established with 53,878 sq ft building of which 35,621 sq ft is UCRETE lapping production floor able to produce 30 MT per day. The UCRETE floor, built upon German technology, ensconces no food contamination, impervious, non-absorbent, anti-microbial production area.

The plant is equipped with two best classes Plate Freezers from Mycom, Japan and World base, China each of which has the capacity to freeze 500 kg per load in 1.5-2 hours and blast freezer from UK with the ability to freeze 4 MT per load in 3-3.5 hours. This facility is also equipped IQF Freezer from NTSQUARE, China having 500 kg/hr freezing capacity with two glazing & hardening chamber and one steam cooking line, 300kg/hr. The product core temperature is maintained -18oC in every freezing process line to extend the product shelf life and its quality.

ACI Agrolink Limited is furnished with Three cold storages, two of which have the capacity to hold 250 MT and another one has the capacity to hold 100 MT, where temperature maintain between -18 to -22o C. Combined total 12 units compressors concocted refrigeration system, 10 units from SABROE, Denmark and 2 units from KILOSKAR, India, ensures European standard cooling system. It has two chill storages of 450 sq ft each for raw materials along with a dry storage of 1000 sq ft for packaging and additives.

The in-house water treatment plant (WTP), RO and UV system is used for the water treatment system which supplies safe water to every phase of the production process ensuring the best quality salubrious product.

Two flake ice plants with 40 MT capacity per day with ice formed with in-house WTP treated water, indemnify the ice production for the entire production process to ensure the best quality product.

The factory is equipped with in-house sub-station, facilitate with 630 KVA transformer, for electricity supply. Two stands by generator from YORPOWER, UK with 550 KVA and FMW, China with 60 KVA to secure uninterrupted 24-hour power back up.

It has also Effluent Treatment Plant (ETP) to purify waste water and release safe water to environment to protect the nature.

Amian shrimp has well-organized in-house laboratory with neoteric lab appliances including stomacher, incubator, autoclaves (auto pressure and temperature control), distill water plant, colony counting, compound microscope potentially able to perform microbial test for water, ice and shrimp which can detect E. coli, Salmonella, Vibrio cholera, standard plate count, and total coliform bacteria. Additionally chemical test of water for the parameters of pH, TDS, Iron, Hardness, Chlorine and Arsenic are also performed.

A permanent doctor is always there for the employees. All employees are schemed with regular health check-up once a year. Also, health insurance policy is available for the employees.

Childcare room and entertainment room are also available for the employee recreation.

There are in-house training facilities where employees are getting trained under the leadership of HACCP’s team leader every month. Employees are provided training regarding food safety and quality, occupational health and safety, as well as social and environmental compliances. They are also assessed after training.

Amian shrimp has well-organized in-house laboratory with neoteric lab appliances including stomacher, incubator, autoclaves (auto pressure and temperature control), distill water plant, colony counting, compound microscope potentially able to perform microbial test for water, ice and shrimp which can detect E. coli, Salmonella, Vibrio cholera, standard plate count, and total coliform bacteria.

A permanent doctor is always there for the employees. All employees are schemed with regular health check-up once a year. Also, health insurance policy is available for the employees.

Childcare room and entertainment room are also available for the employee recreation.

There are in-house training facilities where employees are getting trained under the leadership of HACCP’s team leader every month. Employees are provided training regarding food safety and quality, occupational health and safety, as well as social and environmental compliances. They are also assessed after training.