At ACI Agrolink Ltd., economic sustainability is at the heart of our long-term business strategy. We are committed to ensuring efficient, traceable, and market-responsive operations that add value across the supply chain, while maintaining our environmental and social responsibilities. Our approach helps secure stable growth for the company, its employees, and its partners.

Key Economic Sustainability Indicators

- Product Quality and Traceability: Ensuring high-quality shrimp products is central to customer trust and brand integrity. We maintain:

a)Compliance with internationally recognized certifications such as HACCP, BRC, GMP

b) A robust traceability system, enabling shrimp to be traced back to the farm level, ensuring transparency and food safety.

- To strengthen backwards linkage, ACI Shrimp Genetics provides the quality Super PL availability with technical support for the shrimp farmers so that they can increase their farm productivity while ensuring the proliferation of disease-free SPF PL in Kaliganj, Satkhira.

- Raw materials are collected from the registered local & contract farmers to maintain backwards linkage. We support those farmers with training, quality inputs, and regular audits to ensure Good Aquaculture Practices (GAPs) with sustainability standards, ensuring full traceability and export readiness.

2.Yield and Cost Efficiency: Operational efficiency is crucial for profitability and sustainability. We focus on:

a)Optimizing yield rate – maximizing the kilograms of finished product per kilogram of raw shrimp.

b)Continuous implementation of cost optimization strategies through introducing modern technology, training, and waste reduction

3.Market Diversification: A diversified export portfolio enhances our economic resilience and competitiveness by expanding market presence. This includes:

a) Serving a growing number of international export markets, ensuring geographic diversification

b)Increasing the production and sales of value-added products (e.g. breaded shrimp, cooked items) for greater market penetration and profitability.

4.Certifications and Compliance: Certifications are not only compliance tools but also demonstrate our commitment to sustainable practices. ACI Agrolink holds HACCP, BRC, and GMP Certifications.

Through innovation, quality assurance, and responsible operations, ACI Agrolink Ltd. is building a resilient business that delivers long-term value to stakeholders while meeting global sustainability expectations.

Water comes through the river enters into shrimp ponds and shrimps are grown naturally. ACI Agrolink’s brand Amian hrimp collects shrimp from these farmers and process them in their factory located in the middle of the shrimp farming area in mian. The factory is a 43,000 sq ft building with the production capacity of 35 ton per day.

Factory location is giving Amian Shrimp an advantage on quick buying from the local farmers and this initiative also helped the local farmers to develop market linkage and through this they are managing their livelihood.

Amian Shrimp is indirectly saving the nature and directly helping the farmers on shaping a sustainable life.

State-of-the-art shrimp processing factory, compliance and global certifications leading to higher brand image are the drivers of our business.

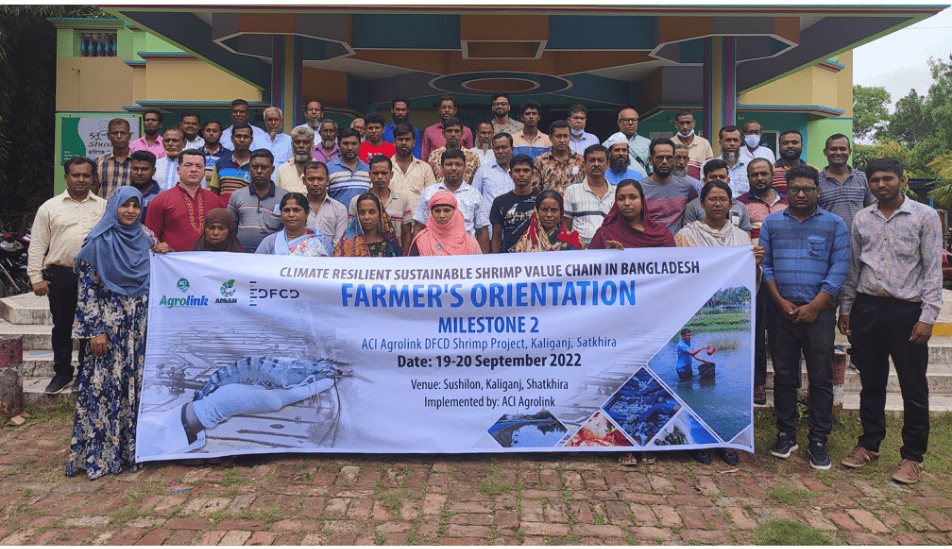

Climate Resilient Sustainable Shrimp Value Chain in Bangladesh

ACI Agrolink DFCD Shrimp Project

Besides being crucial to the macroeconomic development of Bangladesh, shrimp sector sustainability is linked to the livelihoods of millions. Low farm productivity due to climate change coupled with lack of market integration and various compliance requirement are undermining the sustainability of this important sector. Low farm productivity can be linked to a myriad of climatic, management and input related problems while presence of intermediaries in the value chain with redundant roles makes it difficult to comply with food safety standards, leading to low price for their production.

In the southern region of Bangladesh farmers cannot produce any crops due to high salinity. Many farmers depend on Sundarbans for their livelihood as they cannot make enough money from shrimp cultivation. As a result, they make damage to natural habitant and the mangrove forest.

While the project will increase the farm productivity of shrimp and ensure good price with climate resilient sustainable shrimp production, this bottom of the pyramid people will return to land to produce shrimp.

The purpose of this project is to foster an enabling environment that drives shrimp sector to progressively enhance production efficiency and secure uninterrupted international market access while adapting changing climate condition.

The Partnership:

31st May 2022 to till 31 July 2023, through the Dutch Fund for Climate and Development, SNV will be providing ACI Agrolink with technical assistance to develop a business investment proposal on climate resilient black tiger shrimp

Target Population: 100 farmers in Kaliganj, Satkhira

Climate Resilient Sustainable Shrimp Value Chain in Bangladesh

ACI Agrolink Limited-DFCD Shrimp Project

Besides being crucial to the macroeconomic development of Bangladesh, shrimp sector sustainability is linked to the livelihoods of millions. Low farm productivity due to climate change coupled with lack of market integration and various compliance requirement are undermining the sustainability of this important sector. Low farm productivity can be linked to a myriad of climatic, management and input related problems while presence of intermediaries in the value chain with redundant roles makes it difficult to comply with food safety standards, leading to low price for their production.

In the southern region of Bangladesh farmers cannot produce any crops due to high salinity. Many farmers depend on Sundarbans for their livelihood as they cannot make enough money from shrimp cultivation. As a result, they make damage to natural habitant and the mangrove forest.

While the project will increase the farm productivity of shrimp and ensure good price with climate resilient sustainable shrimp production, this bottom of the pyramid people will return to land to produce shrimp.

The purpose of this project is to foster an enabling environment that drives shrimp sector to progressively enhance production efficiency and secure uninterrupted international market access while adapting changing climate condition.

The Partnership:

31st May 2022 to till 31 July 2023, through the Dutch Fund for Climate and Development, SNV will be providing ACI Agrolink with technical assistance to develop a business investment proposal on climate resilient black tiger shrimp

Target Population: 100 farmers in Kaliganj, Satkhira

ACI Agrolink Limited collects shrimp from these farmers and processes them in their factory located in the heart of the shrimp farming area in Amian.

The factory location is giving an advantage on quick buying from the local farmers, and this initiative also helped the local farmers to develop market linkage, and through this, they are managing their livelihood.

ACI Agrolink Limited is indirectly saving nature and directly helping the farmers in shaping a sustainable life.

State-of-the-art shrimp processing factory, compliance, and global certifications leading to a higher brand image are the drivers of our business.

The purpose of this project is to foster an enabling environment that drives shrimp sector to progressively enhance production efficiency and secure uninterrupted international market access while adapting changing climate condition.

Environmental Sustainability Indicators in Operations

To ensure environmentally responsible operations, we monitor and improve performance across the following key sustainability indicators:

1. Effluent Treatment

✅ Presence and operational effectiveness of Effluent Treatment Plants (ETPs)

✅ Compliance with discharge parameters set by the Department of Environment (DoE)

2. Water Use Efficiency

✅ Measurement of water use per kilogram of processed shrimp

✅ Implementation of recycled water systems or rainwater harvesting

3. Energy Use and Emissions

✅ Monitoring of energy consumption per ton of final product

✅ Adoption of renewable energy sources (e.g., solar energy integration)

✅ Tracking of greenhouse gas (GHG) emissions, especially for exports to carbon-conscious markets

4. Waste Management

✅ Environmentally responsible disposal or reuse of solid waste, shrimp shells, and offcuts

✅ Conversion of organic waste into fishmeal, compost, or agricultural fertilizer

5. Chemical Use and Control

✅ Safe storage, handling, and minimal use of chemicals such as phosphates, preservatives, and sanitisers

✅ Strict compliance with international export standards, such as EU Maximum Residue Limits (MRLs)

Climate Resilient Sustainable Shrimp Value Chain in Bangladesh

ACI Agrolink DFCD Shrimp Project

Besides being crucial to the macroeconomic development of Bangladesh, shrimp sector sustainability is linked to the livelihoods of millions. Low farm productivity due to climate change coupled with lack of market integration and various compliance requirement are undermining the sustainability of this important sector. Low farm productivity can be linked to a myriad of climatic, management and input related problems while presence of intermediaries in the value chain with redundant roles makes it difficult to comply with food safety standards, leading to low price for their production.

In the southern region of Bangladesh farmers cannot produce any crops due to high salinity. Many farmers depend on Sundarbans for their livelihood as they cannot make enough money from shrimp cultivation. As a result, they make damage to natural habitant and the mangrove forest.

While the project will increase the farm productivity of shrimp and ensure good price with climate resilient sustainable shrimp production, this bottom of the pyramid people will return to land to produce shrimp.

The purpose of this project is to foster an enabling environment that drives shrimp sector to progressively enhance production efficiency and secure uninterrupted international market access while adapting changing climate condition.

The Partnership:

31st May 2022 to till 31 July 2023, through the Dutch Fund for Climate and Development, SNV will be providing ACI Agrolink with technical assistance to develop a business investment proposal on climate resilient black tiger shrimp

Target Population: 100 farmers in Kaliganj, Satkhira