ACI Agrolink Limited-DFCD Shrimp Project

Besides being crucial to the macroeconomic development of Bangladesh, shrimp sector sustainability is linked to the livelihoods of millions. Low farm productivity due to climate change, coupled with a lack of market integration and various compliance requirements, is undermining the sustainability of this important sector. Low farm productivity can be linked to a myriad of climatic, management and input-related problems, while the presence of intermediaries in the value chain with redundant roles makes it difficult to comply with food safety standards, leading to low prices for their production.

In the southern region of Bangladesh, farmers cannot produce any crops due to high salinity. Many farmers depend on the Sundarbans for their livelihood as they cannot make enough money from shrimp cultivation. As a result, they cause damage to the natural habitat and the mangrove forest.

While the project will increase the farm productivity of shrimp and ensure good prices with climate resilient, sustainable shrimp production, this bottom of these bottom-of-the-pyramid people will return to land to produce shrimp.

The purpose of this project is to foster an enabling environment that drives the shrimp sector to progressively enhance production efficiency and secure uninterrupted international market access while adapting to changing climate conditions.

Project The Partnership:

From 31st May 2022 to 31 July 2023, through the Dutch Fund for Climate and Development, SNV will be providing ACI Agrolink with technical assistance to develop a business investment proposal on climate-resilient black tiger shrimp.

Target Population:

100 farmers in Kaliganj, Satkhira

ACI Agrolink Limited, a subsidiary of ACI Limited is a unique name in Bangladesh for its quality products, innovation, skilled professional management, work culture, business ethics and environmental consciousness. The state-of-the-art factory is designed to deliver the highest level of quality standard and meet the specific needs of the customers.

The factory is a 53,878 sq. ft building with the production capacity of 30 ton per day.

ACI Limited is one of the leading conglomerates with a multinational heritage and has always been driven by its mission, vision and values. ACI’s international recognition also enables Amian Shrimp to ensure all global compliances and certifications, creating a hub of satisfied customers worldwide. The company owns multidimensional facilities to create and deliver the best range of products for its global partners through ensuring premium quality, unwavering commitment and continuous innovation.

Our suppliers are chosen from those who comply with the laws of employment and protection of environment. We encourage and assist our suppliers in becoming more efficient. We ensure that our suppliers provide us materials which conform to the highest standards.

We take care of our environment. All our factories and compliant of the environmental laws. There are policies for quality, safety, Health and Environment which are followed meticulously.

Amian, a trusted brand of ACI Agrolink Limited, has earned a reputation for excellence among customers worldwide. Located at the heart of Bangladesh’s shrimp farming hub, our processing facility ensures that shrimp are processed immediately after harvest, preserving their premium quality for global markets. Backed by industry-leading expertise, world-class quality control systems, and superior processing practices, Amian Shrimp sets the standard for quality and food safety in the industry.

ACI Agrolink Limited, a subsidiary of ACI PLC, is a distinguished name in Bangladesh, known for its commitment to quality, innovation, professional management, strong work culture, ethical business practices, and environmental responsibility. Our state-of-the-art facility is purposefully designed to meet the highest quality standards and fulfil the unique needs of our customers.

As a part of ACI PLC, one of the country’s leading conglomerates with a multinational legacy, Amian Shrimp benefits from the group’s global recognition, ensuring compliance with international standards and certifications. This enables us to build a global network of satisfied customers. With a robust range of multidimensional facilities, ACI Agrolink continuously innovates to deliver premium-quality products, maintaining an unwavering commitment to excellence and creating lasting value for our global partners.

Annual Meet with Stakeholders-2025

The Annual Stakeholders Meeting at ACI Agrolink Factory was successfully held on 22nd April 2025, bringing together a diverse group of stakeholders, including factory workers, employees, suppliers, community members, regulatory representatives. The meeting aimed to review the factory’s annual performance, address key challenges, ensure regulatory alignment, and strengthen collaboration across all stakeholder groups.

ACI Agrolink proudly hosted its Annual Stakeholders Meeting on April 22, 2025, at its factory premises, bringing together a dynamic and diverse group of stakeholders. The event served as a key platform for open dialogue and collaborative reflection, welcoming factory workers, employees, suppliers, community members, and representatives from regulatory bodies.

The meeting focused on reviewing the factory’s performance over the past year, discussing operational and environmental challenges, and reaffirming ACI Agrolink’s commitment to regulatory compliance and sustainable growth. Attendees participated in constructive discussions aimed at enhancing transparency, aligning shared goals, and building stronger partnerships.

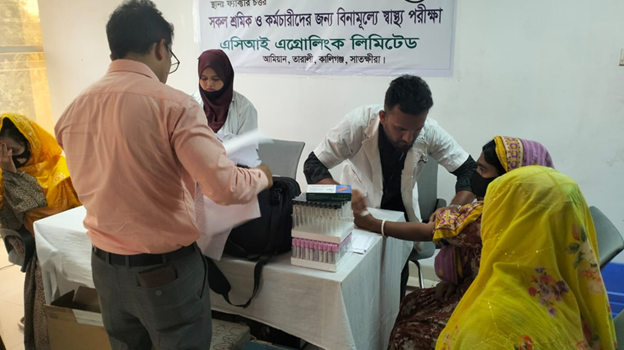

ACI Agrolink Organizes Free Health Check-Up for Factory Employees—

The health camp featured a range of basic medical examinations, including blood pressure monitoring, sample collection, and general health consultations. A dedicated team of medical professionals facilitated the check-ups in a safe, hygienic, and well-organised setting within the factory premises.

The initiative saw active participation from employees across all departments, with a notable turnout of female workers. The primary objectives of the campaign were to promote preventive healthcare, facilitate early diagnosis, and raise health awareness among the workforce.